Digital CNC Packing Box Corrugated Board Vibrating Knife Cutting Equipment with Factory Price

Jinan Kang Jia CNC Equipment Co., Ltd.- Waterproof Rating:IPX-0

- Warranty:1-year

- Certification:CE, ISO 9001:2000, ISO 9001:2008

- Condition:New

- Control:Semi-Automatic

- Application:Paper, Plastic, Leather, Fabric

Base Info

- Model NO.:KJCT-1625

- Power Source:Electric

- Layout:Horizontal

- Safety Device:Infrared Radiation ,Anti-Collision,Emergency Stop

- Cutting Speed:1000mm,S

- Power:110,220,380V

- Repeated Cutting Accuracy:0.1mm

- Transport Package:Wooden Box

- Specification:1600*2500mm

- Trademark:kangjia

- Origin:China

- HS Code:8461500090

- Production Capacity:100sets,Month

Description

Basic Info.

Model NO. KJCT-1625 Power Source Electric Layout Horizontal Safety Device Infrared Radiation /Anti-Collision/Emergency Stop Cutting Speed 1000mm/S Power 110/220/380V Repeated Cutting Accuracy 0.1mm Transport Package Wooden Box Specification 1600*2500mm Trademark kangjia Origin China HS Code 8461500090 Production Capacity 100sets/MonthProduct Description

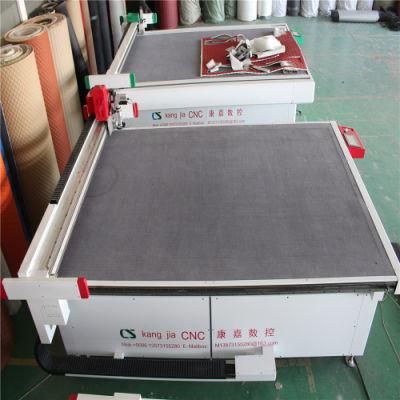

ProductionDigital cnc packing box corrugated board vibrating knife cutting equipment with factory price

| Model | KJCT-1625 (can be customized) |

| Fan power | 9kw |

| Voltage | 110V/220V/380V±10%,50HZ 60HZ |

| Working characteristic | Computer operation and cutting machine at the same time,complete data transmission quickly,can be used continuously |

| Cutting speed | max. 140m/min |

| Cutting thickness | 0.1-50mm |

| Effective cutting area | 2500mm*1600mm |

| Cutting accuracy | ±0.1mm |

| Overall dimension | 3260*2120*1315mm |

| Cutting materials | Corrugated paper,plastic corrugated sheet,grey board,ivory board,film,composite materials,leather ,fabric,slab rubber,pear wool,sponge,KT board etc. |

| Multifunctional head for different cutter | Half knife, full knife, punching roller, V-cutter, milling knife, pneumatic knife, electric knife, Circular knife (round knife / rotary knife); pin |

| Location mode | Infrared laser |

| Material fixed mode | absorption |

| Transmission interface | Network transmission |

| Compatible software | Kangjia intelligent software |

| Control system | LED touch screen |

| Driving mode | Racking drive |

| Drive motor | Delta( /Panasonic/Fuji/Yaskawa optional) |

| Guide rail | Brand :Yintai |

| Body structure | Body welding |

| Suction case | Aluminum case |

| Certification | CE/SGS,ISO9001/ISO14001/ISO18001 |

| Safety device | Mechanical anti-collision device/infrared radiation |

Machine Introduction:

Integrated Welding Steel Constructed Table

The machine is built with a durable, stable, 6mm all-steel tube frame which significantly reduces vibration and gives the operator tight control for precise cutting.

Conveyor System

Designed for easy loading and unloading of materials, the Conveyor System provides operators a fast advance control of material and serves as a vacuum cutting surface ideal for roll materials.

Digital Servo Drive System

Brushless AC Servo Motors, guide rail, rack and pinion are integrated into the machine providing both velocity and torque with uncompromised accuracy for cutting applications.

Safety Device

Equipped with infrared automatic sensor device and four emergency stop buttons, the Safety Device provides a safe working environment.

Accurate and Stable Working Table

The cutting table is built with 7 series aviation aluminum which contains a honeycomb structure inside, sturdy, high-precision, nondeformable, stable for long-term running.

Regional Vacuum Adsorption System

The vacuum adsorption area can be selected according to the size of the materials. By using individual vacuum controls for each area, the vacuum system greatly reduces the need for masking open areas of the table.

Motion Control system

The motion control system consists of a motion controller and a LCD touch control panel. It can make the cutting process smooth, efficient, perfect. And the control panel is quite easy to operate with English interface.

Cutting Heads

The machine can be equipped with one cutting head or multiple cutting heads. Different cutting tools can be changed and mounted on the cutting heads for different cutting needs.

Factory information

Jinan Kangjia CNC Equipment Co., Ltd has focused on CNC equipment production for over 5 years. It is a comprehensive service company specializing in the production, sales and technical service of oscillating knife cutting machine. It covers multiple fields and industries, such as automotive decoration, toys, garment, leather product, furniture etc. Its R&D level and production capacity has always been in the leading position in the same industry. Our factory is located in Jinan city of China. It covers 10000 square meters, with 150 staffs in total. The production capacity is about 100 unit / month.

Certification

Trade Capacity

International Commercial Terms(Incoterms): FOB, CIF, CFR Terms of Payment: LC, T/T Average Lead Time: Peak season lead time: one month, Off season lead time: within 15 workdays Export Year: 2016 Export Percentage:5%-15% Main Markets: North America, South America, Europe, Southeast Asia/ Mideast, Africa, East Asia(Japan/ South Korea), Australia, Domestic Nearest Port: Qingdao Port (can be customized ) Import & Export Mode: Have Own Export LicensePacking and delievery

Our service

Our serviceBefore sales:

- Reply you within 24 hrs for your inquiry or question.

- Learn your detail requirements and what material you will cut. Then recommend the good solution that suit for you.

- Sign sales contract and receive the deposit.

- Arrange production.

- Track the production schedule.

- Debug machine.

- Pack with wooden box and shipping.

- 12 months warranty for the whole machine.

2. Technical support by phone, email or WhatsApp / Skype around the clock.

3. Friendly English version manual and operation video CD disk.

4. If necessary, the fields service can be provided.

1. Delivery time: Within 20 days after receiving the deposit.

2.Payment terms: 50% prepaid, pay off the balance before shipment.

3. Warranty: 1 year quality warranty, except the vulnerable parts (knife, sliding block, limiting stopper, transmission box, cutter fixture.). After 12 months, the seller provide paid maintenance.